The Basics On 7 Common Types of Plastic

In our continuous effort to offer educational tools on plastic pollution and sustainability, we thought we would answer one of the most popular queries we receive: Isn’t plastic all the same? To put it briefly: no.

However, it’s reasonable that many people form the idea that it’s one substance, all the same from top to bottom. There are hundreds of different kinds of plastic (also known as polymers), yet we only deal with a small subset of them on a daily basis.

While we fully endorse efforts to create viable plastic substitutes, the fact is that plastic is and will be for some time. So, rather than dismiss it or criticise it blindly, I propose we work to get a deeper understanding of it. All plastics don’t always have negative outcomes. It’s clear that people’s lives have been improved by it, and there’s even a case to be made that it’s helped the environment, too (albeit only in very particular cases).

Understanding the complexities of recycling, upcycling, and the health effects of plastic requires familiarity with the many plastic varieties. But the crucial word there is “complexity.” Given the breadth of the subject, this article serves only as an introduction for readers with little background information, rather than as an in-depth analysis for those who are already familiar with the issue.

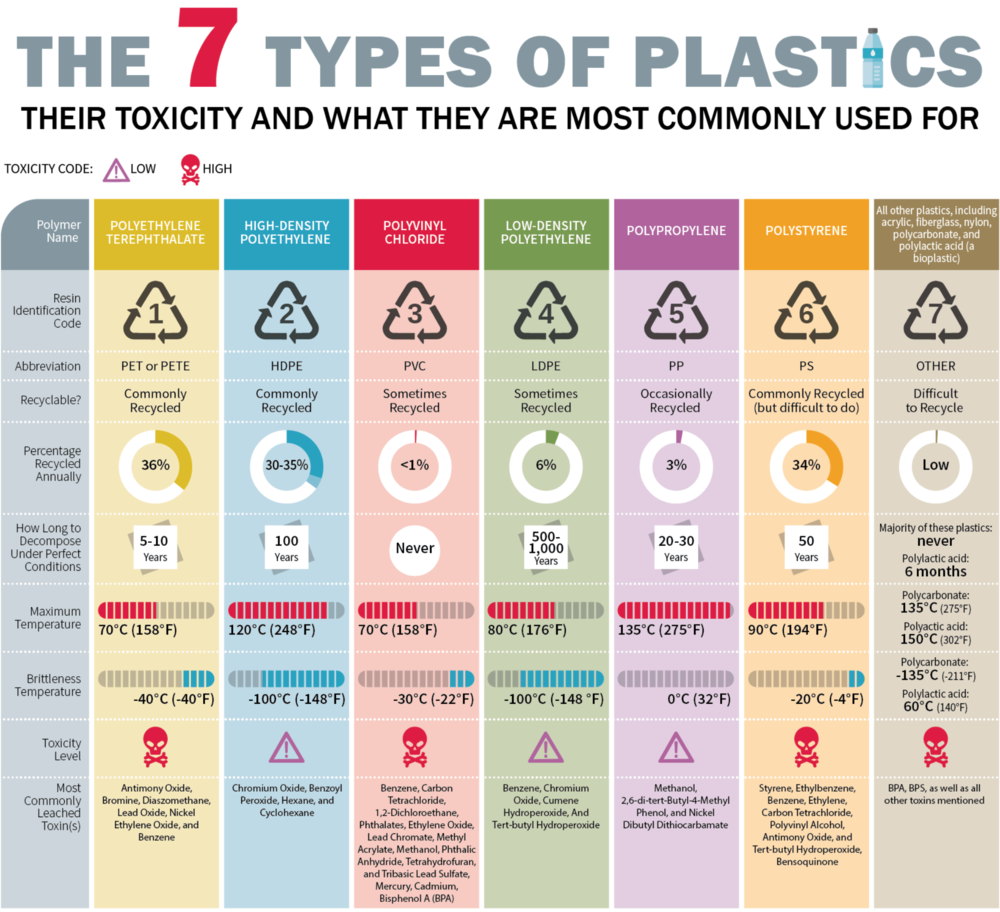

The very first thing we need to do is learn the fundamentals of the most common forms of plastic, which are coded in numerical order so that they may be recycled. Just in case, here’s a quick primer:

Plastic Bottle Recyclers

One of the most widespread uses of PET is in bottles for beverages.

Poly(ethylene) Terephthalate (Number 1) (PET or PETE)

This is one among the most regularly used plastics. It’s lightweight, robust, often transparent and is commonly used in food packaging and textiles (polyester) (polyester).

Examples: Beverage bottles, Food bottles/jars (salad dressing, peanut butter, honey, etc.) and polyester clothes or rope.

High-Density Polyethylene (HDPE) (HDPE)

Collectively, Polyethylene is the most prevalent plastics in the world, but it’s classed into three types: High-Density, Low-Density and Linear Low-Density. Because of its durability and resistance to moisture and chemicals, High-Density Polyethylene is widely used in packaging, transportation, and construction.

Examples: Milk cartons, detergent bottles, cereal box liners, toys, buckets, park seats and stiff pipes.

IV plastic fluid bags and tubing

Medical bags and tubing are a frequent Polyvinyl Chloride product.

Poly(vinyl chloride) (PVC or Vinyl)

This strong and stiff plastic is resistant to chemicals and weathering, making it wanted for building and construction purposes; while the fact that it doesn’t transmit electricity makes it popular for high-tech uses, such as lines and cable. It’s also commonly utilised in medical applications since it’s impermeable to germs, is readily cleansed and allows single-use applications that decrease infections in healthcare. On the other hand, it’s important to remember that PVC is the most toxic kind of plastic to humans since it releases harmful chemicals at every stage of its existence (eg: lead, dioxins, vinyl chloride).

Water pipes, credit cards, toys for both humans and animals, rain gutters, teething rings, intravenous fluid bags, medical tubing, and oxygen masks are just a few examples.

Low-Density Polyethylene (LDPE) (LDPE)

A variant of HDPE that improves upon the original by being suppler, more transparent, and more adaptable. It’s common use is as a liner for beverage cartons, but it also finds usage in items like corrosion-resistant countertops and other surfaces.

Cling wrap, sandwich and bread bags, bubble wrap, trash bags, supermarket bags, and drink containers are just a few examples. For LDPE Granules Traders service you can click the link for more information.

Polypropylene (PP)

You won’t find a more sturdy plastic than this one. Food packaging and storage that is designed to contain hot foods or be heated itself may benefit from its higher heat resistance compared to other materials. It can be bent somewhat without breaking, yet it keeps its form and durability for quite some time.

Examples: Straws, bottle caps, prescription bottles, hot meal containers, packing tape, disposable diapers and DVD/CD boxes (remember them!).

a polyethylene foam often known as Styrofoam

Styrofoam, or polystyrene, is a popular packaging material.

Polystyrene (PS or Styrofoam)

Styrofoam, as this stiff plastic is more often known, is inexpensive and provides excellent insulation, making it widely used in the food, packaging, and construction sectors. Polystyrene, like polyvinyl chloride, is a material that has been linked to health problems. Styrene, a neurotoxic, is only one example of a toxin that may readily seep out and be absorbed by food, making its way into human bodies. We provide PP Granules Traders India sevice all over in india if you looking for service then click the link or contact us through the mail.

Cups, takeaway containers, shipping and product packaging, egg cartons, cutlery, and insulation are all examples of common disposable items.

Other

The notorious “other” choice! This category is a catch-all for various sorts of plastic that don’t belong in any of the other six categories or are mixtures of numerous types. We mention it because you can sometimes run into the #7 recycling code, so it’s vital to know what it implies. The most essential issue here is that these polymers aren’t often recyclable.

Examples: Eyeglasses, infant and sports bottles, gadgets, CD/DVDs, lighting fixtures and transparent plastic flatware.

There you have it — the most prevalent plastics we use every day. This is clearly extremely basic knowledge on a subject that one might spend months on investigating. The manufacture, circulation, and consumption of plastic are all intricate processes. We invite you to delve in further in order to comprehend all these subtleties, such as plastic characteristics, recyclability, health dangers and alternatives, including the advantages and downsides of bioplastics.

Read more:- click